Liquid Coating Line

The most flexible solution for painting methods.

The Liquid Coating Line is an automated production line for the coating of liquid materials. It consists mainly of coating equipment, conveyor systems, control systems and paint supply systems. Liquid coating lines are used in a wide range of industrial applications such as automotive manufacturing, furniture manufacturing, metalworking and building decoration.

Flexibility in terms of coating methods and application areas. The following are some of the distinctive features of liquid spray lines:

- Efficient spraying: high spraying speed enables large areas to be coated in a short time.

- Wide range of applications: can be used in a variety of industrial applications such as automotive manufacturing, furniture manufacturing, metalworking and architectural decoration, as well as in artistic creation and sign painting.

- Flexibility and adaptability: spray head can be adjusted in angle and position to suit a wide range of painting requirements and to ensure uniformity and integrity of spraying.

- Colour and effect versatility: liquid spray lines can be adapted to achieve a wide range of colours and effects by adjusting the spraying parameters and using different spraying materials.

Distinctive features of liquid coating lines include high coating efficiency, coating quality control, a wide range of applications, flexibility and adaptability, as well as a wide choice of colours and effects. These features make the liquid spray line an important tool in modern coating processes.

Proven

30 years of experience providing proven equipment

Lifetime Service

Maintenance is more important than repair

Maximum Efficiency

Production line capacity fully matches demand without wasting any resources

Product Description

The most distinctive feature of a liquid coating line is its flexibility in terms of coating methods and application areas. The following are some of the distinctive features of liquid spray lines:

- Efficient spraying: the liquid spray line allows for a fast and efficient coating process by spraying the liquid material evenly onto the target surface with the spray head. The high spraying speed enables large areas to be coated in a short time.

- Wide range of applications: Liquid spray lines are suitable for spraying a wide range of materials, including paints, lacquers, varnishes, and adhesives. They can be used in a variety of industrial applications such as automotive manufacturing, furniture manufacturing, metalworking, and architectural decoration, as well as in artistic creation and sign painting.

- Flexibility and adaptability: the liquid spray lines are suitable for target surfaces of different shapes and sizes, including flat surfaces, curved surfaces, and complex structures. The spray head can be adjusted in angle and position to suit a wide range of painting requirements and to ensure uniformity and integrity of spraying.

- Color and effect versatility: liquid spray lines can be adapted to achieve a wide range of colors and effects by adjusting the spraying parameters and using different spraying materials. This makes the liquid spray line an important tool for individual and customized painting, meeting the needs of different customers and markets.

Wide range of applications

Liquid paint spraying lines are used in a wide range of industries and sectors, the following are common applications for liquid paint spraying lines:

- Automotive manufacturing: The liquid paint spray line plays an important role in the automotive manufacturing process. It is used for the painting of car bodies, including the application of primers, topcoats, and varnishes to protect the surface and provide a cosmetic effect.

- Furniture manufacturing: The liquid paint spray line is widely used in the furniture manufacturing industry for spraying coatings on furniture surfaces to add decorative effects and protect the surface of the wood. It is suitable for a wide range of furniture such as tables, chairs, cabinets, and beds.

- Metalwork processing: The liquid spray paint line can be used for surface coatings of metalwork, such as metal furniture, doors and windows, metal pipes, and mechanical parts. Spray coatings provide a protective coating that prevents corrosion and enhances the appearance of metal.

- Architectural decoration: In the construction industry, liquid spray paint lines are used to paint building facades, interior walls, and ceilings. It provides weathering and decorative effects while protecting building materials.

- Electronics manufacturing: The liquid spray paint line is also used in the manufacture of electronics. It is used for the painting of electronic product casings such as mobile phones, TVs, computers, and appliances to enhance the appearance and protect the surface of the casing.

- Woodworking: The liquid spray paint line is used in the woodworking industry, such as cabinets, wooden floors, doors, and windows. Spray coatings can provide wood protection and decorative effects.

- Artistic and sign painting: Liquid spray paint lines are also used for artistic and sign painting. Artists and designers can use spray technology to achieve creative painting effects, while sign manufacturers also use liquid spray paint lines for painting signs and billboards.

Manual water curtain paint spray booth

An advanced paint spraying equipment that effectively controls pollution and safety risks during the spraying process.

Highly efficient filtration, Safe, Reduces paint deposits

Dry circulating air spray booths

Reliable and effective paint spraying equipment for a wide range of applications in the painting industry, such as automotive manufacturing.

High efficiency filtration, Clean working environment

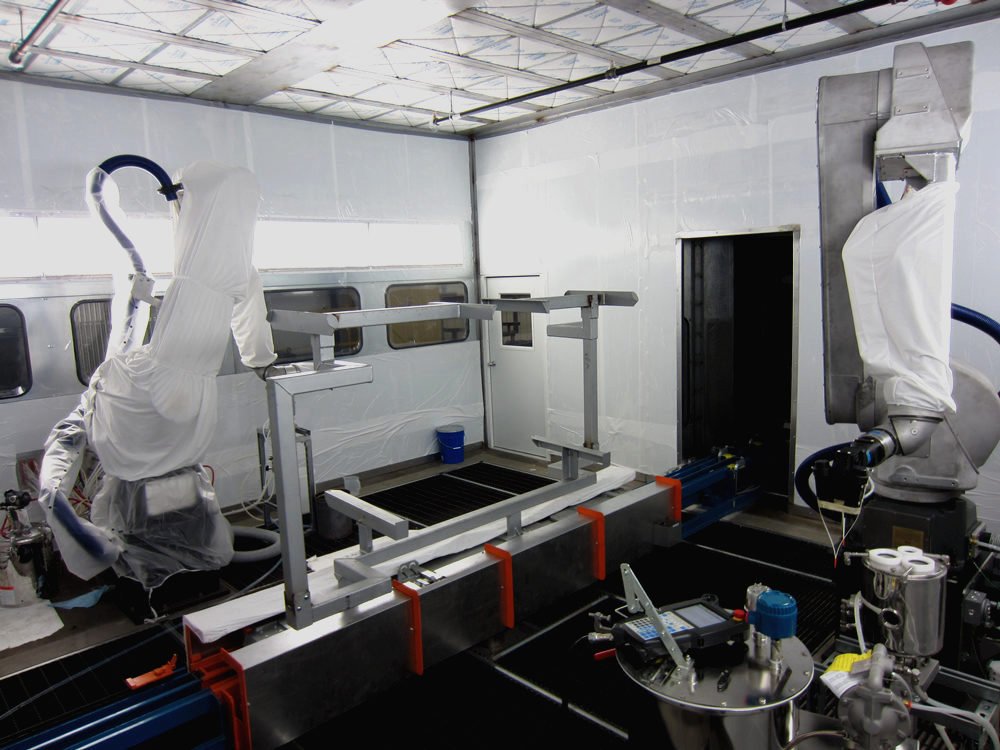

Product Images

Product Feature

- Highly customisable: our line designs are highly customisable and can be adapted and modified to suit your requirements. Our dedicated team will work with you to ensure that the line is perfectly suited to your specific production process and product requirements.

- Advanced technology and innovation: we are constantly pursuing technological breakthroughs and improvements to ensure our products are at the forefront of the industry in terms of performance and efficiency.

- Quality and reliability: Our lines are designed to undergo rigorous quality control and testing, using quality materials and components to ensure long life and high performance, thus providing you with a reliable production solution.

- Ease of operation: Our lines are designed with ease of operation in mind, reducing operator training costs and the potential for operator error. Our interfaces and control systems have been carefully designed to ensure simple and intuitive operating processes, while providing the necessary functionality and flexibility.

- Maintenance and support: comprehensive after-sales service and support, including training, regular maintenance and technical support. Our dedicated team will ensure that you are able to use the line to its full potential and provide you with rapid response and problem solving support when required.

Need a design plan, now?

Application Case

FAQ

Our liquid spraying equipment is suitable for a wide range of industries and applications. They can be used in automotive manufacturing, furniture manufacturing, metalworking, plastics, aerospace, architectural decoration and many more. Liquid spraying equipment can cope with the surface coating needs of different materials, including metal, plastic, wood and more. Whether you are looking for a high quality paint finish in the automotive industry or a fine finish in furniture manufacturing, our liquid spray equipment will meet your requirements.

Liquid spraying equipment has several advantages. Firstly, liquid spraying provides a uniform, smooth and continuous finish, resulting in a superior coating quality. Secondly, liquid spraying equipment is suitable for a wide range of pigments and coatings to meet different colour and effect requirements. In addition, liquid spraying allows for high coating speeds and increased productivity. Finally, liquid spraying equipment is highly adaptable and can be adapted to different shapes and sizes of workpieces, providing a high degree of flexibility.

Yes, our liquid spray equipment can provide environmentally friendly coating solutions. We focus on using low VOC (Volatile Organic Compounds) coatings and environmentally friendly spraying techniques to reduce our environmental impact. Our equipment is also equipped with advanced coating control systems and filters to minimise emissions of exhaust gases and waste, ensuring that the painting process meets environmental standards.

Yes, our liquid spraying equipment is designed to be simple and easy to operate. We focus on user-friendliness to ensure that operators can easily master the operation of the equipment. In addition, we provide detailed user manuals and training to help your team get up and running quickly. As for maintenance, our equipment is built with reliable components and systems that reduce the frequency and complexity of maintenance work. We also provide regular maintenance instruction and after-sales follow-up to assist our customers with regular maintenance of their equipment.

Yes, we offer a custom design service for liquid spray equipment lines. We understand that each customer’s needs and requirements are unique, so our dedicated team will work with you to customise the design to your specific needs. Whether it is customisation for specific workpiece sizes and shapes or for specific coating processes and production requirements, we will ensure that the line is perfectly suited to your needs and provide a solution that meets your expectations.