Home » Products » E-coating System Accessories » Washing Equipment

Washing equipment

Improving the utilisation of electrophoretic paint

Efficient cleaning equipment is essential for electrophoresis lines. In the electrophoretic coating process, the cleanliness of the painted surface directly affects the quality of the coating and adhesion. Our water washing equipment offers a wide range of cleaning options, including spray, immersion, and submersible, to meet the cleaning needs of different workpieces. The quality and efficiency of our equipment is impeccable and offers the following advantages:

- Highly efficient cleaning capacity.

- A variety of cleaning methods.

- Improved coating quality.

- Easy to operate.

In summary, our washing machines offer the advantages of high cleaning capacity, a wide range of cleaning methods, improved coating quality, and ease of operation in the electrophoretic coating. The quality and efficiency of our machines are impeccable and meet the high demands of our customers for cleaning equipment.

Product Description

Efficient cleaning equipment is essential for electrophoresis lines. In the electrophoretic coating process, the cleanliness of the painted surface directly affects the quality of the coating and adhesion. Our water washing equipment offers a wide range of cleaning options, including spray, immersion, and submersible, to meet the cleaning needs of different workpieces. The quality and efficiency of our equipment is impeccable and offers the following advantages:

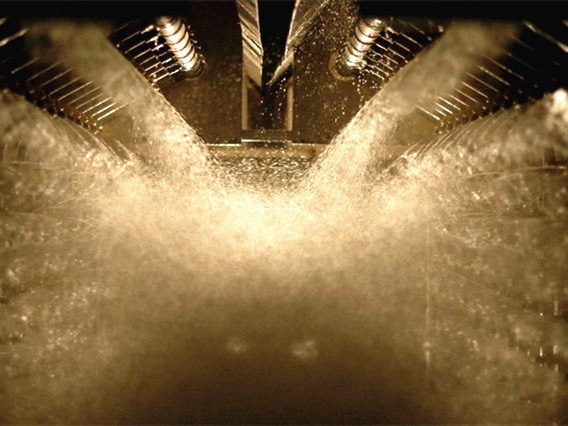

- Highly efficient cleaning capacity: our water washing machines feature advanced nozzles and spray systems that provide a uniform water flow and high-pressure rinsing effect, effectively removing grease, dirt, and other impurities from the surface of workpieces. Whether small or large pieces, our equipment can clean efficiently and increase productivity.

- A variety of cleaning methods: Depending on the characteristics of the workpiece and the cleaning requirements, our machines offer a variety of cleaning methods such as spray, immersion, and submersion. The spray type is suitable for surface cleaning, the immersion type for pre-treatment before painting, and the submersible type for complex workpieces. Our machines are flexible and can be customized to suit the customer’s needs.

- Improved coating quality: By thoroughly cleaning the surface of workpieces of grease, dirt, and other impurities, our water washing equipment ensures the adhesion and consistency of the coating during the painting process. A clean surface helps to distribute the paint evenly, reducing the appearance of paint defects and imperfections and improving the quality of the coating.

- Easy to operate: Our washers are designed to be easy to use and are equipped with an intuitive operator interface and control system for easy operation and monitoring by the user. The automated functions and intelligent design make it easier to run the machine, saving labor and time costs.

In summary, our washing machines offer the advantages of high cleaning capacity, a wide range of cleaning methods, improved coating quality, and ease of operation in the electrophoretic coating. The quality and efficiency of our machines are impeccable and meet the high demands of our customers for cleaning equipment.

Product Features

- Highly efficient cleaning capacity.

- A variety of cleaning methods.

- Improved coating quality.

- Easy to operate.

Need a design plan, now?

FAQ

Washing equipment plays a vital role in electrophoretic spraying. Its main role is to clean the surface of the workpiece, removing grease, dirt and other impurities and providing a clean workpiece base for the coating process. Through the use of washing equipment we can ensure that the paint adheres evenly to the surface of the work piece, improving the quality and durability of the coating.

Our water washing machines offer a variety of cleaning methods to suit the needs of different workpieces. Common cleaning methods include spray, immersion and submersible. Spray is used for surface cleaning, where dirt is washed away by a high pressure stream; immersion is used for pre-treatment, where the workpiece is immersed in the cleaning solution to dissolve the dirt; and submersion is used for complex workpieces, where the workpiece is completely immersed in the cleaning solution for cleaning.

Our water washing machines provide a uniform water flow and high pressure rinsing effect through efficient cleaning methods and advanced nozzle design to ensure a thoroughly clean surface. A clean surface facilitates even paint distribution and adhesion, reducing the appearance of paint defects and imperfections and improving paint quality and durability.

Our water washing machines are designed to be simple to use and easy to operate. We offer an intuitive operator interface and control system that allows users to easily operate and monitor. In addition, our machines are equipped with automation features and intelligent design for automatic cleaning and maintenance, reducing manual intervention and management costs.

The maintenance interval for water washing equipment depends on a number of factors, such as frequency of use, type of workpiece and water quality conditions. In general, we recommend regular cleaning and maintenance to ensure the performance and effectiveness of the equipment. Our machines are equipped with intelligent monitoring and reminders to remind you of maintenance work and to ensure proper operation and a long life of the machine.