Home » Products » E-coating System Accessories » Electronic Control System

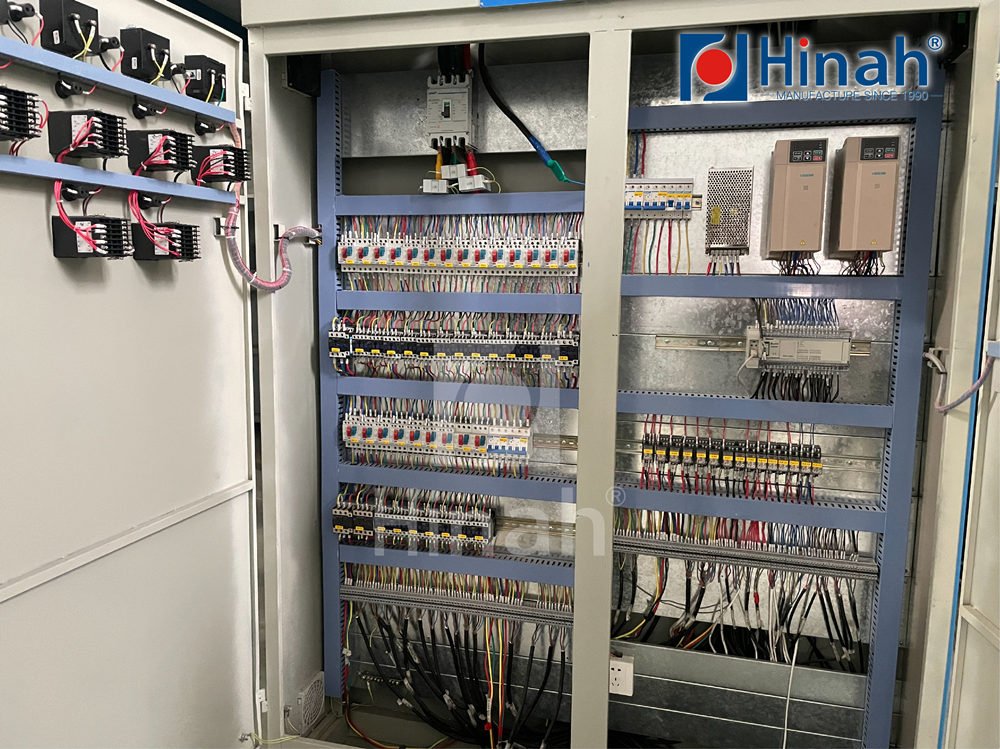

electronic control system

Precisely the right temperature for efficient electrophoresis

The electronic control system of the electrophoretic coating line is the core technology platform to ensure the stability and efficiency of the coating process. It uses advanced automation control technology to comprehensively monitor and adjust various parameters in the electrophoretic coating process, including current, voltage, temperature, paint concentration, etc., to provide precise process control for the production line. The system can respond to different process requirements in real-time, automatically adjust coating parameters, ensure coating quality consistency, improve production efficiency, and effectively reduce manual intervention and production costs.

The integration and intelligent design of the electronic control system make operation easier, support remote control and monitoring, and meet complex production needs. Whether in large-scale coating production lines or the production environment of small and medium-sized enterprises, the system can provide reliable performance support to ensure efficient, energy-saving, and environmentally friendly production processes.

Product Description

The electric control system has the characteristics and important role of automatic control, multifunctionality, linkage control and data analysis in electrophoretic coating equipment. It is the key component to ensure precise control, stable operation and quality optimization of the coating process.

- Control the coating parameters: the electronic control system can precisely control the key parameters in the coating process, such as current, voltage and time. By adjusting these parameters, the thickness, uniformity and quality of the coating can be controlled to meet the coating requirements.

- Monitoring and diagnosis: The electronic control system can monitor various parameters and signals in the coating process in real time, such as coating flow, electric field strength, temperature, etc.. If there is any abnormality, the system can carry out fault diagnosis and send out alarm signals in time to ensure the safety and stability of the painting process.

- Optimization of process: By recording and analyzing the data in the coating process through the electronic control system, process optimization and parameter adjustment can be carried out. According to the results of data analysis, the coating process can be improved to enhance the coating efficiency, quality and energy consumption control.

- Realize intelligent management: The electronic control system can realize intelligent management of the painting process through the technology of communication with the upper computer and network. Through remote monitoring and remote control, it can realize remote management and trouble shooting of painting equipment, and improve production efficiency and management benefits.

Intelligent electronic control system

System Advantages

- Improve production efficiency: Through automated control and real-time data monitoring, manual operations are reduced, production efficiency and process stability are improved, and errors and time wasted in the production process are reduced.

- Accurate coating control: The system can accurately adjust current, voltage, and other parameters to ensure high consistency of coating quality, reduce over-coating or under-coating, and improve coating uniformity and adhesion.

- Energy saving and environmental protection: Accurately control current, voltage, and paint usage, effectively reduce energy waste and paint volatilization, reduce paint consumption, and also comply with environmental regulations.

- Intelligence and remote control: The intelligent design of the system enables the production line to run automatically without supervision, and supports remote monitoring and adjustment, which improves the automation level of the production line.

- Reduce maintenance costs: Built-in fault self-diagnosis and alarm functions help to promptly identify and solve problems in the production process, reduce equipment failure downtime, and reduce maintenance costs.

Product Features

- Precise control

- Efficient energy utilisation

- Fast response

- Stability and reliability

- Providing stable temperature control of the painting process

- Ensuring quality and productivity.

Need a design plan, now?

FAQ

Our electronic control system plays a key role in electrophoretic coating. It is responsible for monitoring and controlling the entire electrophoretic coating process to ensure even distribution and precise control of the paint. Through the electronic control system, we are able to regulate the temperature of the electrophoresis tank, the current, the paint spraying and the rotation speed, and other parameters to achieve high-quality coating results.

Our electronic control system uses advanced algorithms and sensor technology to monitor the paint flow in the electrophoresis tank in real time. Through accurate feedback information, the electronic control system can automatically adjust the current and spraying speed to ensure that the coating is evenly distributed on the surface of the workpiece, avoiding uneven coating thickness or leakage.

Our electronic control system is equipped with sophisticated measuring and control equipment, which can monitor parameters such as paint concentration and pH value in the electrophoresis tank in real time. Based on the preset coating formula and quality requirements, the electronic control system automatically adjusts the current and spray volume to ensure precise coating control. This prevents too much or too little paint and ensures consistent coating quality for each workpiece.

Our electronic control system has multiple safety measures built in to ensure the safety of the operator and the equipment. For example, it is equipped with an overload protection device that automatically stops the coating process when the current exceeds the set range, preventing overheating of the electrophoresis tank and equipment damage. In addition, our system is equipped with an emergency stop button and guards to quickly cut off the power supply and protect operator safety in case of emergency.