Environmental & Accessories

A more efficient and versatile finishing area.

Electrophoretic coating lines are large in scale and include many functional stages, such as pre-treatment equipment, washing equipment, electrophoretic bath equipment, water treatment equipment, air treatment equipment, and environmental control equipment. The pretreatment equipment is usually washed several times, while the electrophoresis bath equipment also consists of water treatment equipment, electrophoresis paint equipment, thermostatic equipment, electrodes, and power supply equipment. Each of these pieces of equipment has a unique function. Auxiliary and environmental equipment is often categorized as follows.

- Water tank thermostats

- Ultra-filtration equipment

- Washing equipment

- Environmental equipment (waste, wastewater treatment equipment)

Depending on the size and requirements of the painting line, there may be other specific equipment and systems, such as circulation pumps, automatic conveying systems, painting robots, etc.

Proven

30 years of experience providing proven equipment

Lifetime Service

Maintenance is more important than repair

Maximum Efficiency

Production line capacity fully matches demand without wasting any resources

Product Description

Electrophoretic coating lines are large in scale and include many functional stages, such as pre-treatment equipment, washing equipment, electrophoretic bath equipment, water treatment equipment, air treatment equipment, and environmental control equipment. The pretreatment equipment is usually washed several times, while the electrophoresis bath equipment also consists of water treatment equipment, electrophoresis paint equipment, thermostatic equipment, electrodes, and power supply equipment. Each of these pieces of equipment has a unique function. Auxiliary and environmental equipment is often categorized as follows.

- Tank thermostats: During the electrophoretic coating process it is important to maintain a constant temperature of the paint and water in the tank. Bath thermostats are used to control the temperature in the electrophoresis bath to ensure the quality of the paint and the consistency of the coating.

- Ultra-filtration equipment: During the electrophoretic coating process, ultrafiltration equipment can effectively remove particles and impurities from the paint to improve the purity and stability of the paint. The ultrafiltration equipment achieves the separation and removal of impurities through filtration technology.

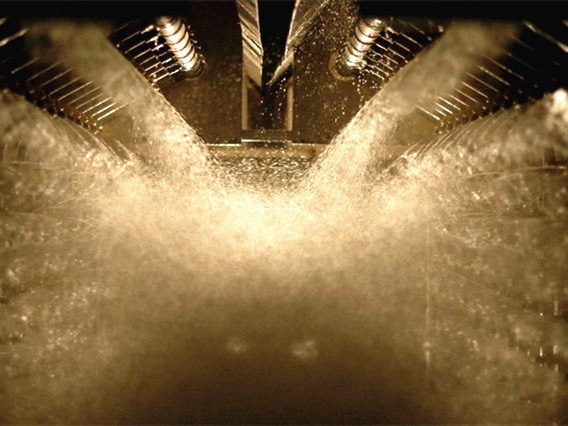

- Washing equipment: After the electrophoretic coating is completed, the workpiece usually needs to be washed to remove excess paint and chemicals. Washing equipment can include washing tanks, spray systems, etc. for thorough cleaning of the workpiece to ensure the quality and appearance of the coating.

- Environmental equipment (waste air/wastewater treatment equipment): Environmental equipment is also essential as waste and wastewater are generated during the electrodeposition coating process. This includes waste treatment equipment, such as waste collection systems and waste treatment equipment, and wastewater treatment equipment, such as wastewater treatment systems and purification equipment, which are used to treat and dispose of the waste and wastewater generated to meet environmental requirements.

These are important auxiliary and environmental equipment in electrophoretic painting and can help you achieve better painting results and environmental management. Please note that in practice, the exact equipment and system configuration may vary depending on the size and requirements of the coating line. Depending on the size and requirements of the paint line, there may be other specific equipment and systems such as circulation pumps, automatic conveying systems, painting robots, etc. The specific selection of auxiliary and environmental equipment will be tailored to the coating process, product type, and production requirements.

In the electrophoretic coating line, in addition to auxiliary equipment and environmental equipment, there is two crucial equipment, which are the core components of the electrophoretic bath equipment: electrophoretic tank and dosing system.

- E-coat tank: The e-coat tank is a key equipment in the electrophoretic coating process. It is used to hold the electrophoretic paint and make the paint evenly adhere to the surface of the workpiece to be coated by applying an electric field. The e-coat tank is usually made of corrosion-resistant materials and can withstand the corrosion of the electrolyte. Its design and management directly affect the coating quality and production efficiency. The performance and status of the electrophoretic tank need to be regularly inspected and maintained to ensure the stability and consistency of the electrophoretic coating process.

- Dosing system: The dosing system is used to automatically add various chemical agents, such as catalysts, dispersants, stabilizers, etc. to the electrophoretic tank to ensure the best performance of the electrophoretic coating. These chemicals help to improve the coating effect and ensure the uniformity, adhesion, and durability of the coating. The dosing system is usually equipped with an automatic monitoring device to accurately control the amount and ratio of the agent added, thereby ensuring the coating quality and the long-term stability of the electrophoretic tank liquid.

As important components of the electrophoretic coating line, these two devices not only determine the quality and stability of the coating process but also directly affect production efficiency and environmental friendliness.

Tank Thermostats

Advanced and intelligent heating ovens and heat exchange plates to control the temperature of the liquid in the electrophoresis tank, so that the temperature is always kept within a constant range and the electrophoresis efficiency is more efficient.

Highly accurate, intelligent and energy efficient

Ultra-filtration Water Equipments

More advanced, applying the latest filtration technology to form a fully closed-loop water circulation system, easily renewable consumables and more cost-effective modular replacement parts, more environmentally friendly and more efficient.

Environmentally friendly, efficient and low maintenance.

Washing Equipments

Efficient washing equipment is essential for electrophoresis lines, whether spray or dip tank or submersible, the quality and efficiency of our equipment is impeccable.

Efficient, logical and necessary washing sessions

Environmental Equipments

State-of-the-art exhaust and waste water treatment facilities make the environmental impact of our production limited and manageable. Bringing water back to water and air back to air.

Advanced, efficient, environmentally friendly and low energy consumption.

Need a design plan, now?

Application Case

FAQ

As a supplier, we offer a wide range of ancillary equipment that can be customised to suit your painting needs. Common ancillary equipment includes pre-treatment equipment (e.g. wash tanks, degreasing equipment), drying equipment (e.g. ovens, hot air drying equipment), water treatment equipment (e.g. water treatment systems, waste water treatment equipment) and dust removal equipment (e.g. filters, dust collectors). Our team will provide the best auxiliary equipment solution to suit your needs and line layout.

As a supplier, we place a high priority on the quality and performance of our auxiliary equipment. We use high quality materials and advanced manufacturing processes to ensure the durability and reliability of our equipment. In addition, we carry out stringent quality control and testing to ensure that each piece of equipment meets specifications and standards. We also provide performance data and test reports on our equipment for your reference and verification.

We offer a comprehensive range of environmental solutions, including waste and wastewater treatment equipment. Our waste treatment equipment can be used to collect and treat waste materials generated during production processes and take appropriate measures for recycling or safe disposal. Meanwhile, our waste water treatment equipment can be used to purify and treat the waste water generated during the painting process, ensuring compliance with environmental regulations and discharge standards.

Yes, we offer a customised ancillary equipment service to suit your plant layout and specific requirements. Our dedicated team will work with you to understand your needs and requirements and will design and customise the equipment to suit your plant layout. We are committed to providing you with the best solution to ensure that the equipment fits closely with your production line and achieves optimum efficiency.