Home » Products » E-coating Line » Accumulation Conveyor E-coating Line

Accumulation Conveyor E-coating Line

Flexible and efficient e-coating system.

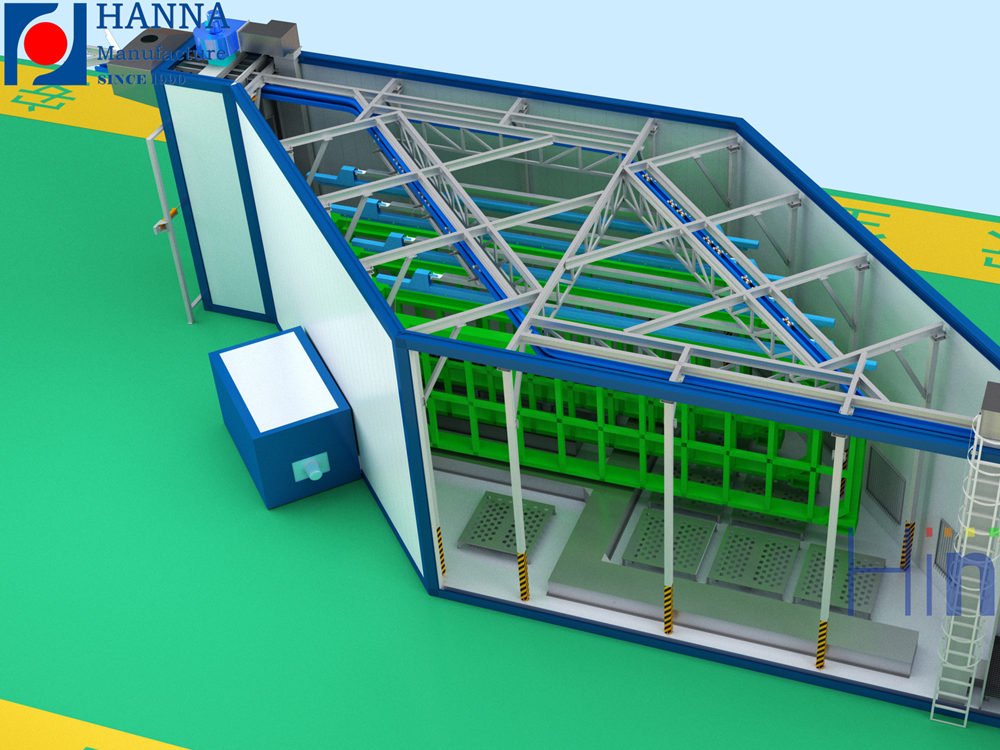

The accumulation conveyor e-coating line is a transfer system for the application of electrodeposition coating which combines accumulation transfer and e-coating technology. In this system, workpieces are transferred one by one through the accumulation transfer line to the coating area and then treated with an electrophoretic coating. .

Advantages and features:

- Batch coating capability.

- Automated operation.

- Flexibility.

- Cost saving.

- Quality control.

Accumulation conveyor e-coating line combines accumulation transfer and electrodeposition coating technology, widely used in a variety of painting applications, such as automotive manufacturing, furniture manufacturing and metalwork painting, to achieve efficient, high-quality painting operations.

Product Description

The accumulation conveyor e-coating line is a transfer system for the application of e-coating which combines accumulation transfer and electrodeposition coating technology. In this system, workpieces are transferred one by one through the accumulation transfer line to the coating area and then treated with an electrophoretic coating. The following features of the accumulative electrodeposition coating line are available and highlight the advantages of accumulative transfer:

Batch coating capability: The accumulation-type e-coating line is suitable for high volume coating requirements. It is capable of carrying multiple workpieces and enables efficient painting operations through continuous transfer and handling. This increases productivity and reduces painting cycles.

Automated operation: The accumulation e-coating line uses an automated control system for the automatic transfer of workpieces and the coating process. By setting programs and parameters, automatic start/stop, speed adjustment and coating time control can be achieved, reducing the risk of human error and improving the consistency of coating quality.

Flexibility: The accumulation conveyor e-coating line has a certain degree of flexibility. It can accommodate the painting of workpieces of different shapes, sizes and materials, including flat, curved and complex three-dimensional shapes. This makes it suitable for diverse painting needs, from small parts to large workpieces that can be painted on the same line.

Cost saving: The accumulation electrodeposition coating line makes efficient use of work space and maximises painting efficiency. It can be laid out and arranged according to the size and coating requirements of the workpiece, reducing wasted space and lowering unit coating costs.

Quality control: The accumulation conveyor e-coating line enables accurate control of the coating parameters through precise control systems and coating devices. This ensures consistent coating quality and appearance of each workpiece, improving quality control.

In summary, the accumulation conveyor e-coating line combines accumulation transfer and electrodeposition coating technology, offering advantages such as batch coating capability, automated operation, flexibility, cost savings and quality control. It is widely used in a variety of painting applications, such as automotive manufacturing, furniture manufacturing and metalwork painting, to achieve efficient, high-quality painting operations.

Advantage:

Batch transfer: The accumulation conveyor e-coating line is suitable for the transfer of large quantities of material or products. It usually has a large carrying capacity and can transfer several materials or products at the same time, improving productivity and logistical efficiency.

Automated operation: The accumulation conveyor line uses an automated control system to achieve automatic start/stop, speed adjustment and material diversion. This reduces the need for manual operation and increases the level of automation and operational stability of the line.

Flexibility: The accumulation conveyor line is flexible and highly adaptable. It can accommodate the transfer of materials or products of different shapes, sizes and weights, including flat, curved and three-dimensional shapes.

Customisable: The accumulation conveyor line can be custom designed to meet customer requirements. Depending on the specific requirements of the material or product, the length, width, height, speed and other parameters of the transfer line can be adjusted to meet specific production needs.

Integration with other equipment: accumulation conveyor lines can be integrated with other production equipment, such as assembly machines, packaging machines, etc. This integration enables an automated production process, improving productivity and the overall operation of the line.

Applicable applications:

The accumulation conveyor line is a common type of industrial transfer equipment, mainly used for the continuous transfer of materials or products in production lines. It has the following characteristics:

Batch transfer: The accumulation conveyor line is suitable for the transfer of large quantities of material or products. It usually has a large carrying capacity and can transfer several materials or products at the same time, improving productivity and logistical efficiency.

Automated operation: The accumulation conveyor line uses an automated control system to achieve automatic start/stop, speed adjustment and material diversion. This reduces the need for manual operation and increases the level of automation and operational stability of the line.

Flexibility: The accumulation conveyor line is flexible and highly adaptable. It can accommodate the transfer of materials or products of different shapes, sizes and weights, including flat, curved and three-dimensional shapes.

Customisable: The accumulation conveyor line can be custom designed to meet customer requirements. Depending on the specific requirements of the material or product, the length, width, height, speed and other parameters of the transfer line can be adjusted to meet specific production needs.

Integration with other equipment: accumulation conveyor lines can be integrated with other production equipment, such as assembly machines, packaging machines, etc. This integration enables an automated production process, improving productivity and the overall operation of the line.

Overall, the accumulation conveyor line offers batch transfer, automated operation, flexibility and customisability. It is used in a wide variety of production areas, such as manufacturing and logistics and warehousing, to achieve efficient, automated material or product transfer.

Product Features

- Highly automated

- Uniform coating

- Large batch processing

- Flexibility

Learn more about the details ?

FAQ

Accumulating electrodeposition lines are suitable for many types of workpieces, including automotive bodies and components, electronic equipment housings, furniture, metalwork, industrial equipment and more. Whether it is a small part or a large workpiece, a flat surface or a complex three-dimensional shape, our accumulative electrodeposition coating lines can meet your needs.

Accumulation lines provide consistent and uniform coating results. With precise control systems and coating devices, we can ensure a high quality coating and a satisfactory appearance for each part. Whether it is a protective, decorative or special effect coating, we can meet your coating requirements.

Yes, we offer customised design and manufacturing services. Depending on your workpiece size, coating requirements and production process, we can customise the CEP line to best meet your specific requirements. Whether it’s line length, load capacity, speed control or other parameters, we will work with you to ensure that the equipment is a perfect fit for your production environment.

Our accumulative electrophoresis coating lines use advanced automation control systems to achieve a high level of automated operation. From workpiece transfer to all stages of the painting process, it is capable of automated start/stop, speed adjustment and control of painting parameters. This not only improves production efficiency but also ensures quality and consistency of coating.

Yes, our CEP lines are equipped with precise quality control. Through strict control of the coating parameters and real-time monitoring, we ensure consistent coating quality and appearance of each part. We can also provide quality inspection and testing services to ensure that the product meets your quality standards.