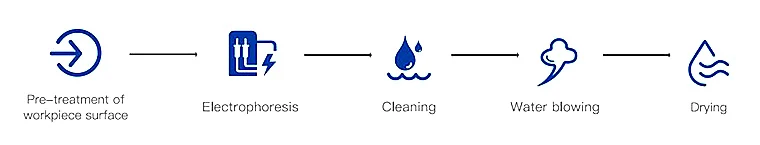

Electrophoretic Coating line

The Most Efficient Painting Solution.

We provide our clients with exactly matched designs, reliable equipment, and safe, complete, and efficient production e-coating systems. Electrophoretic coating line is also known as the Electro-Deposition coating line, ED coating line, E-coat systems, Electrocoat systems, or E-coat dipping.

Electrophoretic coating lines can be classified according to different standards.

According to the electrode polarity of the electrophoretic process, it can be divided into two types: cathodic electrophoresis and anodic electrophoresis. According to the transmission mode and structure, electrophoretic coating lines can be divided into Monorail E-coating Line, Gantry Stepping E-coating line, Accumulation Conveyor E-coating Line and Trolley Hoists E-coating Line. Different electrophoretic coating lines are suitable for different workpieces.

Proven

30 years of experience providing proven equipment

Lifetime Service

Maintenance is more important than repair

Maximum Efficiency

Production line capacity fully matches demand without wasting any resources

Product Description

Electrophoresis coating line is a coating method that uses an electric field to disperse the paint evenly in an aqueous solution and then deposit it on the surface of the coated object. The electrophoretic coating line can be divided into two types: cathodic electrophoresis and anodic electrophoresis, and different electrophoresis methods are selected according to the material and performance of the coated object.

The characteristics of electrophoretic coating line:

- High efficiency: The electrophoretic coating line can realize continuous or intermittent automatic production, which improves production efficiency and quality stability.

- Energy saving and environmental protection: The electrophoretic coating line adopts a closed cycle spraying system, which reduces the consumption of water and solvent, reduces the emission of wastewater and exhaust gas, and meets the requirements of environmental protection.

- Excellent performance: The electrophoretic coating line can make the coating uniform, dense, and smooth on the surface of the object to be coated, with good adhesion, corrosion resistance, wear resistance, and other properties.

◆ Components of electrophoresis equipment:

① Tank body — ② Stirring circulation system — ③ Electrode device — ④ Perature adjustment device — ⑤ Paint supply device — ⑥ Ultrafiltration device — ⑦ Ventilation device — ⑧ Power supply device — ⑨ Washing device after e-coating — ⑩ Paint storage device.

◆ Program control mode:

Imported relay, time relay control PLC+touch screen control.

◆ Performance characteristics:

1. High degree of automation.

2. Reliable operation.

3. Product out high production efficiency.

4. Consistent mass production of coatings.

5. Precise controllable coating thickness.

Uniform plating, no dead angle

The workpiece is covered 360° in all directions by liquid coating, and the coating is uniform, which solves the dead angle of coating.

High production efficiency, high degree of automation.

High efficiency, high utilization

The ultra-high electrophoretic paint utilization rate can reach 95%, energy saving, and environmental protection.

Widest range of application, high efficiency, good controllability

Suitable for complex shapes

It can achieve simultaneous coating of all surfaces of complex shapes, with uniform, flat and strong coverage.

Suitable for large and super-large structural parts

Electrophoretic coating line features

Electrophoretic coating has high paint utilization, fast speed, and strong adhesion, providing rust and corrosion resistance. It is a safe and environmentally friendly painting method that is versatile and compatible with various materials. The coating film dries quickly and has good spreading properties.

1. High paint utilization, safe and environmentally friendly.

2. Good permeability, uniform coating film, and fast speed with strong adhesion.

3. Rust and corrosion resistance, versatile and compatible with various materials.

4. Quick drying with good spreading properties.

Description:

The electrophoretic paint production line (e-coating line) is a type of equipment used in the automated painting process and is widely used in the production of automobiles, home appliances, construction, and furniture. Electrophoretic paint is an anti-corrosion, anti-rust, anti-corrosion, and anti-pollution coating that improves the appearance and service life of products. The following is a brief description of the equipment and role of the electrophoretic paint production line.

Electrophoresis tank:

The electrophoresis tank is one of the core equipment of the painting line and is usually made of steel or polyethylene material. The bath is usually filled with electrophoresis fluid, which is used to deposit the paint evenly onto the surface of the workpiece by the action of the electric field.

Pre-treatment equipment:

The pre-treatment equipment mainly includes processes such as oil removal, rust removal, and phosphating, through which dirt and oxides on the surface of the workpiece can be removed, making it easier for the surface of the workpiece to bond with the paint.

Washing equipment:

In the electrophoretic paint production line, the paint needs to be washed before it is applied to the surface of the workpiece. The washing equipment usually has several stations to clean and rinse the surface of the workpiece by spraying and soaking.

Ovens:

Ovens are used to cure the electrophoretic coating and to improve the wear and corrosion resistance of the coating. Ovens usually consist of heaters, fans, exhaust ducts, etc.

Cooling equipment:

Cooling equipment is used to cool the workpiece to prevent problems such as deformation or discoloration of the coating after drying.

Automatic conveying equipment:

Automatic conveying equipment is used to automatically convey workpieces to improve production efficiency and coating quality.

The role of the electrophoretic paint production line is to deposit the paint evenly on the surface of the workpiece to form a layer of anti-corrosion, anti-rust, anti-corrosion, and anti-pollution electrophoretic coating.

The thickness and quality of the coating can be controlled by adjusting the parameters of the electrophoretic paint production line.

With the electrophoretic paint production line, the quality and appearance of the product can be improved, the service life of the product can be extended and production costs and environmental pollution can be reduced.

Monorail E-coating Line

Flexible and efficient e-coating system, the most versatile and extensive solution.

High production efficiency, high degree of automation.

Gantry Stepping E-coating line

Electrophoretic coating has high paint utilization, fast speed, and strong adhesion.

Widest range of application, high efficiency, good controllability

Trolley Hoists E-coating Line

Electrophoretic coating has high paint utilization, fast speed, and strong adhesion.

Applicable to large and super large structural parts

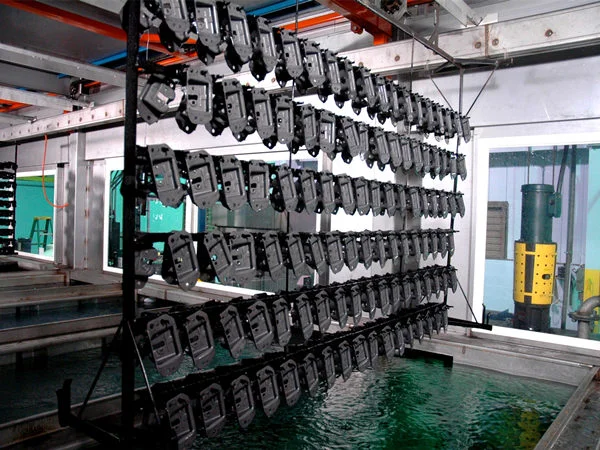

Product Images

Need a design plan, now?

Technical Parameter

| Type Item | QXY1600 | QXY2000 | QXY2500 | QXY3000 | QXY3500 | QXY4000 | QXY4500 | QXY5000 | ||

| Steel Plate | Width | m | 0.8-1.5 | 0.8-2 | 0.8-2.5 | 1-3 | 1-3.5 | 1-4 | 1-4.5 | 1-5 |

| Thickness | mm | 4-60 | 4-60 | 4-80 | 4-80 | 4-100 | 4-100 | 4-100 | 4-100 | |

| Length | m | 1.5-12 | 1.5-12 | 2-12 | 2-12 | 3-16 | 3-16 | 3-20 | 3-20 | |

| Steel Profile | Section Max. size | mm | 40×40 | 60×80 | 60×80 | 60×80 | 80×100 | 80×100 | 80×100 | 80×100 |

| Section Min. size | m | 0.8×0.3 | 1×0.3 | 1×0.4 | 1×0.4 | 1×0.4 | 1×0.4 | 1×0.4 | 1×0.4 | |

| Length | m | 2.4-12 | 2.4-12 | 2.4-12 | 2.4-12 | 2.4-12 | 2.4-12 | 2.4-12 | 2.4-12 | |

| Steel Structures | Max. Width | m | 1 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 |

| Max Height | m | 0.2 | 0.25 | 0.3 | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | |

| Length | m | 2.4-12 | 2.4-12 | 2.4-12 | 2.4-12 | 2.4-12 | 2.4-12 | 2.4-12 | 2.4-12 | |

| Roller Conveyor | Permissible load | T/m | 1 | 1 | 2 | 2 | 2 | 3 | 3 | 4 |

| Conveying Speed | m/min | 1-6 | 1-6 | 1-6 | 1-8 | 1-8 | 1-8 | 1-8 | 1-8 | |

| Coating Thickness | um | 15-45 | ||||||||

| Total Power | KW | 380 | 420 | 520 | 640 | 710 | 810 | 900 | 1100 | |

| Overall Dimension | m | 60x10x6.8 | 62x12x7.32 | 80x12x7.5 | 100x12x7.6 | 120x14x7.7 | 140x14x7.8 | 180x15x7.9 | 200x16x8 | |

Product Feature

- Environmental protection: Electrophoretic coating is water-soluble and does not contain organic solvents, which greatly reduces environmental pollution and fire hazards.

- Coating utilization rate: The coating utilization rate of electrophoretic coating can reach 90% to 95%, which saves 40% more than powder coating.

- Coating quality: The electrophoretic coating is thin and uniform, smooth and flat, with high strength, strong adhesion, corrosion resistance, and good permeability, and can cover workpieces of complex shapes.

- Production efficiency: The production efficiency of the electrophoretic coating is high, and the degree of mechanization is high, so it is easy to realize automatic production and improve labor productivity.

- Low temperature curing: The low temperature curing performance of electrophoretic coating reduces the cost and energy consumption of baking and curing.

Learn more about the details ?

Application Case

Product Video

Need an electrophoresis line planning?

PDF Document

Shot Blasting Machine

- Thirty years of production and design experience on shot blasting.

- Equipment gets the international certification: CE, ISO14001, ISO9001, TUV, BV.

- Get a government-granted endorsement of trust. ATHI is trustworthy.

- All designs adopt 3D Design.

- OEM&ODM factory, High-quality after-sales service

- All adopt general parts, easy to buy and replace.

- Domestic certificate: AAA corporate certificate (The first AAA enterprise in Qingdao).

Need an electrophoresis line planning?

FAQ

Yes, our electrophoretic coating equipment meets the industry standards and certification requirements. Our equipment has undergone strict quality control and testing to obtain relevant certifications, such as ISO certification, CE certification, etc. We ensure that the quality and performance of our equipment can meet your needs.

Answer: Yes, we can customize the equipment according to your coating process requirements. We have a team of professional engineers and experienced technicians who can work with you to ensure that the configuration and parameters of the equipment will meet your specific requirements. We will provide detailed technical solutions and process flows and ensure that the equipment will achieve the coating results you need.

Answer: Yes, our electrodeposition coating equipment is high performance and energy efficient. We use advanced technology and design to optimize the energy efficiency of our equipment and reduce energy consumption. We also offer advanced automatic control systems for precise control of the coating process and reduced paint waste. With our equipment, you can get high efficiency and environmentally friendly coating results.

Answer: Yes, we provide comprehensive after-sales service and maintenance support. We have professional after-sales team and technicians who can provide services such as installation and commissioning, operation training, troubleshooting and repair of the equipment. We also provide the supply and replacement of equipment spare parts to ensure the normal operation and long-term reliability of the equipment. We will establish a long-term relationship with you to ensure that you receive timely and professional support during the use of your equipment.

Answer: Yes, we have a wealth of successful cases and testimonials from satisfied customers. We have worked with many industry leading customers and provided them with high quality electrodeposition coating equipment and services. We can show you our case studies and customer testimonials to prove our competence and professionalism.

Answer: Yes, our electrodeposition coating equipment has good safety performance and complies with the relevant safety standards. We adopt advanced safety design and protection measures to ensure the safety of the equipment during operation. Our equipment has undergone rigorous safety testing and certification and complies with international safety standards to ensure the safety and security of our customers.

Answer: Yes, we have the ability and flexibility to customize our equipment. We understand that each customer’s needs are unique, so we can customize equipment to meet your specific requirements. Whether it’s equipment specifications, functional configuration or design, we can work with you to customize the equipment to meet your specific needs. Our team of engineers has extensive experience in customization and will provide you with expert technical support.

Answer: Yes, our equipment is highly reliable and stable. We select high quality materials and components and ensure the stability and long-term reliability of our equipment through strict quality control and testing processes. We also perform comprehensive equipment testing and validation to ensure stable operation under a wide range of operating conditions, and provide appropriate warranty and maintenance support.

A: Yes, our equipment is scalable and upgradable. We design our equipment with scalability in mind, taking into account the future growth and changing needs of our customers. Our equipment has a modular design and flexible configuration options that allow for upgrades and expansions based on customer needs. This allows customers to easily upgrade their equipment to increase production capacity and efficiency as their business grows.

Answer: Yes, we are committed to technological innovation and providing advanced coating solutions. We continually monitor the latest technologies and trends in the industry and are constantly improving our equipment and processes. Our team of engineers has the technical knowledge and experience to provide our customers with innovative coating