Electrophoretic coating and powder coating are two common surface coating processes, which are widely used in industrial manufacturing.

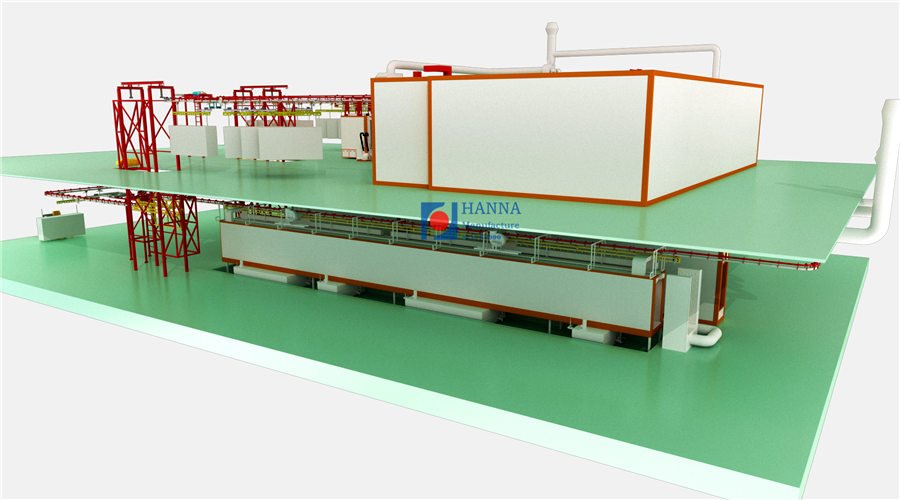

Electrophoretic coating line and powder coating line are important equipment to realize these two processes, and they have some differences in operation principle, application scope and advantages.

This article will introduce the differences between electrophoresis coating line and powder coating line and the advantages of electrophoresis coating line.

I. Difference of operation principle:

Electrophoretic coating line:

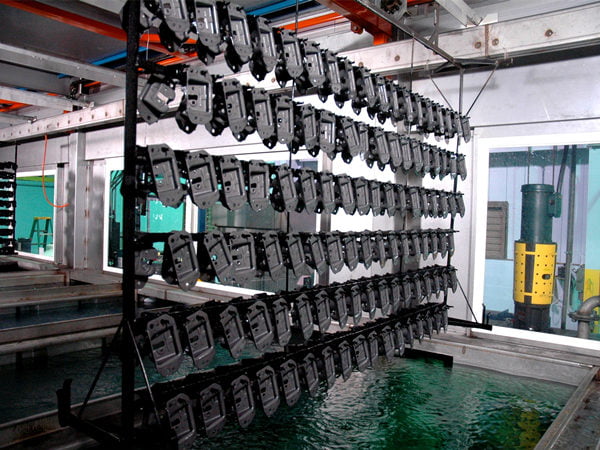

electrophoretic coating is a coating process that uses the action of electric field to make the electrophoretic coating adhere to the surface of the workpiece. In the electrophoretic coating line, the workpiece is immersed in the electrophoretic tank, and by applying voltage and current, the electrophoretic coating forms a uniform and dense coating film on the surface of the workpiece. This coating process can realize the efficient utilization and uniform distribution of the paint.

Powder coating line:

Powder coating is a coating process that electrostatically sprays solid granular powder coating onto the surface of the workpiece. In a powder coating line, the coating is applied to the workpiece by means of electrodes through the spraying equipment and then cured after heating and drying to form a coating film. This coating process allows for efficient coating speed and a wide range of color options.

II. Difference in scope of application:

Electrodeposition coating line:

Electrodeposition coating is suitable for workpieces with electrical conductivity, such as metal products. It can provide excellent corrosion resistance and adhesion, and can form a uniform coating on the surface of workpieces with complex shapes and small voids. Therefore, electrodeposition coating is widely used in automobile manufacturing, furniture manufacturing, metal products and other industries.

Powder coating line:

Powder coating is suitable for many types of workpieces, including metal, wood, plastic, etc. It can provide good wear resistance and weather resistance, and can achieve uniform coating on different workpiece sizes and shapes. Powder coating is widely used in furniture, construction, electrical appliances and other industries.

III. Difference of advantages:

Advantages of electrophoretic coating line:

- Good coating uniformity:

Electrophoretic coating can form a uniform and dense coating on the surface of the workpiece, including complex shapes and small voids.

- Excellent corrosion resistance:

Electrophoretic coating has excellent corrosion resistance, which can effectively protect the surface of workpiece from chemical substances and environmental factors.

- High paint utilization rate:

Since electrophoretic coating achieves paint adhesion through the action of electric field, it can achieve high paint utilization rate and reduce paint waste.

Advantages of powder coating line:

- Diverse color choices:

Powder coating has a wide range of color choices, which can meet the needs of different industries and consumers.

- Efficient coating speed:

Powder coating can realize fast and continuous coating process and improve production efficiency.

- Environmental protection:

Powder coating does not contain organic solvents, which meets the environmental protection standard and reduces the pollution to the environment.

V. Conclusion

To sum up, there are some differences between electrophoretic coating line and powder coating line in terms of operation principle, application scope and advantages.

Electrophoretic coating lines are suitable for workpieces with electrical conductivity and can provide excellent corrosion resistance and uniform coating, while powder coating lines are suitable for many types of workpieces with diverse color options and efficient coating speed.

According to different needs and workpiece characteristics, choosing the suitable coating process and equipment can achieve high quality surface coating.